Power Coating Workshop:

This area is dedicated to applying powder coating to various products, providing a durable and high-quality finish.

Folding Machine:

Used for precise folding of metal sheets and other materials to create specific shapes and components.

400-ton WORLD Brand Mechanical Press:

A heavy-duty press machine capable of handling large-scale metal pressing operations with high efficiency.

Welding Robot:

Automated welding robot ensures consistent and high-quality welds, enhancing the structural integrity of the products.

Automatic Edge Banding Machine:

This machine is used for applying edge bands to panels, ensuring smooth and durable edges for furniture and other products.

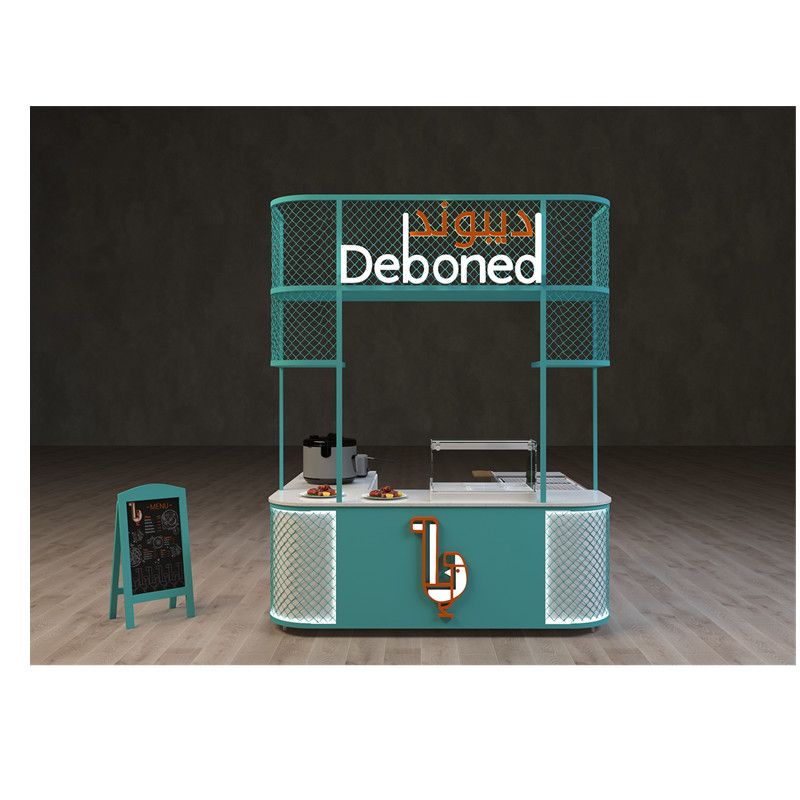

Automatic Welded Wire Mesh Machine:

Specializes in creating welded wire meshes used in various industrial and construction applications.

Digital Shower:

Utilized for precision cutting and shaping of materials using digital controls, ensuring high accuracy and consistency.

Cold Express Machine:

Designed for processing materials that require cold treatment, enhancing their strength and durability.

Engraving Machine:

This machine is used for engraving designs, patterns, and text onto various materials, providing customization options.

Acrylic Workshop:

Dedicated to working with acrylic materials, including cutting, shaping, and assembling acrylic products.

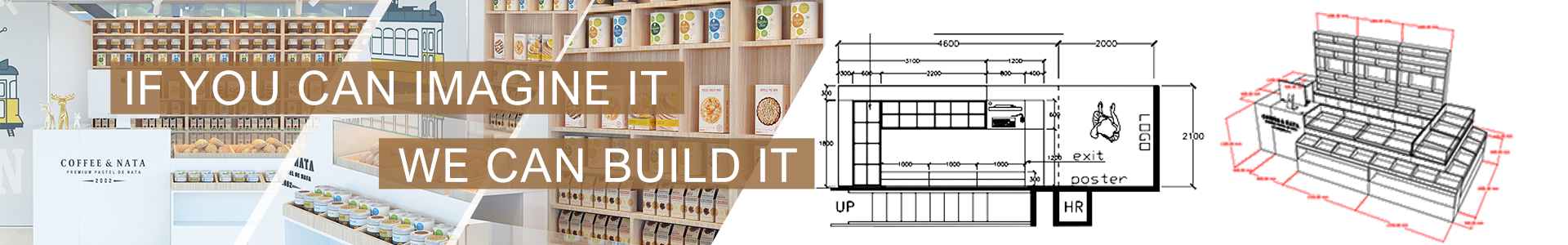

This comprehensive setup allows for efficient production and high-quality output across various manufacturing stages.

Advanced Technology: The workshop is equipped with state-of-the-art machinery that ensures precision and efficiency in all manufacturing processes.

Skilled Workforce: Trained professionals operate the machinery and oversee the production processes to maintain high-quality standards.

Versatile Capabilities: From metal pressing and welding to powder coating and acrylic processing, the workshop can handle a wide range of manufacturing needs.

Quality Control: Each section has strict quality control measures in place to ensure that all products meet the required specifications and standards.

Advanced Technology: The workshop is equipped with state-of-the-art machinery that ensures precision and efficiency in all manufacturing processes.

Skilled Workforce: Trained professionals operate the machinery and oversee the production processes to maintain high-quality standards.

Versatile Capabilities: From metal pressing and welding to powder coating and acrylic processing, the workshop can handle a wide range of manufacturing needs.

Quality Control: Each section has strict quality control measures in place to ensure that all products meet the required specifications and standards.