Quality control: all-round guarantee to ensure perfect project delivery

1.Internal comprehensive inspection

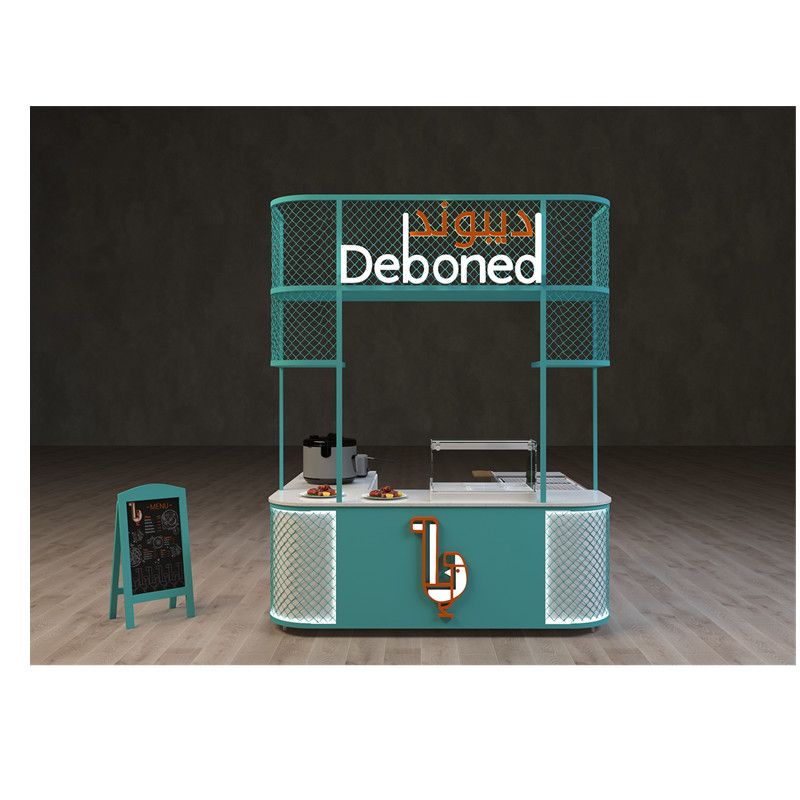

Before the project is packaged and shipped, we fully assemble all customized devices and components according to the final design or 3D rendering, simulate the customer's installation process, and discover and solve potential problems in advance. Through internal pre-installation quality testing, we ensure that all problems are properly resolved before delivery. At the same time, we provide a tested installation manual, and the "ready-to-use" design allows customers to install without worries

2.Key points of pre-installation process

Structural rationality and durability: strictly test the installation structure to ensure that the

design is reasonable, stable and durable.

Installation difficulty assessment: "Ready-to-use" design and process ensure that the installation is simple and easy to understand, without professional experience.

Hardware accessories adaptability: select high-quality hardware accessories to ensure that there is no looseness or abnormal noise after installation.

Electrical system inspection: comprehensive inspection of lighting, lines and transformers to ensure safety and reliability.

Surface and process defect inspection: carefully check the surface of the product to ensure that there are no scratches, cracks, or color differences.

Product quantity verification: count the products and accessories to ensure the accuracy of the quantity and avoid installation delays.

3. Strong and safe transport packaging

All products are packed in wooden crates for easy transportation. Commercial kiosks, mobile carts, stalls or shop projects are designed to be "disassembled and ready to use" and can be easily disassembled and reassembled. We provide a complete video guide and installation instructions to help customers complete the installation easily.

4. Feedback and support after delivery

We deliver projects to the highest standards, focusing on the safety of packaging and transportation. Before loading, we will take photos and videos of the products and send them to customers for confirmation. Customers can visit the factory or arrange inspections at any time to ensure complete satisfaction with the products.

5. Project quality assurance

Although we strictly control quality, accidental damage may occur during transportation. In case of damage, please provide photos or videos and contact the sales consultant. We will analyze and provide solutions through internal meetings to ensure the smooth progress of the project.

Choose us

WhatsApp: +86 13600904631

Email: raymond@super-edisplay.com

you will get a full range of quality control services from production to after-sales, to escort your commercial kiosk, mobile cart, stall or shop project and help your business success. Contact us.